New trailer underride guards regulations promise fewer trucking tragedies, but some worry that they’re “too little, too late”.

With truck crash deaths at crisis levels, the National Highway Traffic Safety Administration (NHTSA) and U.S. regulators adopted stricter standards for rear impact guards on tractor trailers in 2022. According to Transport Topics, “The National Highway Traffic Safety Administration has finalized a rulemaking that updates two truck rear underride guard standards it said will improve protection for drivers and passengers in light vehicles in the event of a rear underride crash.”

This move is the latest in a series of regulatory changes to commercial trucking safety systems intended to improve the safety of our roads; other measures have included collision avoidance technology (e.g., collision warning,) automatic emergency braking, lane departure warning technology, and improved braking systems.

Rear guards on truck trailers are now required to “provide sufficient strength and energy absorption to protect occupants of compact and subcompact passenger cars impacting the rear of trailers” at 35 mph (56 km/hour). Underride guards mounted on the rear of trailers have been shown to prevent serious injury and death in the event of an underride collision.

Until recently, trailers from seven of the eight largest manufacturers in North America showed poor performance in rear underride crash tests: a fact this new ruling hopes to remedy. The difference is stark:

Under this new regulation, rear impact guards must be able to withstand higher forces. Previous standards were based on speeds of 48 km/h (roughly 30 mph). According to NHTSA administrator Steven Cliff, “this new rule will improve protection for passengers and drivers of passenger vehicles.” The rule will take effect 180 days after publication in the Federal Register, with a compliance date of two years after Federal Register publication. Manufacturers have two years to comply with this regulatory adjustment from the date of their federal registry; nine major trailer manufacturers have already adopted the stricter Insurance Institute of Highway Safety (IIHS) standards.

Frequently Asked Questions About Underride Crash Guards

What is an underride crash?

According to the IIHS: “In an underride crash, a passenger vehicle goes partially or completely under a truck or trailer, increasing the likelihood of death or serious injury to the passenger vehicle occupants.” Common reasons for underride crashes include truck driver fatigue, road conditions or the truck drivers’ poor training.

How common are underride crashes?

According to a 1997 study by the IIHS, underrides occurred in about 50% of all crashes. Of those, 57% involved the front, 22% involved the rear, and 20% involved the side.

How do underride accidents happen?

Trucking underride accidents typically happen in three ways:

- Rear-end crash: a smaller vehicle strikes the back of the trailer and becomes wedged beneath it. This can occur when a truck driver stops suddenly, fails to use appropriate signals, or cuts corners in an emergency stop situation and does not provide sufficient warning for other drivers.

- Side-impact crash: This occurs when the smaller vehicle impacts the side of the truck’s trailer. This most commonly occurs at an intersection where a truck driver has made an unsafe turn, merged lanes inappropriately, or changed lanes without signaling or checking blind spots.

- Offset crash: These types of underride crashes occur when the smaller vehicle hits a corner of the trailer. These usually occur during a turn, in which the truck driver does not check to make sure the coast is clear.

How do truck drivers and trucking carriers cause underride accidents?

A truck driver may commit several moving violations that can cause an underride crash: inattentive driving, failure to check blind spots when merging, changing lanes without signaling or looking to make sure no cars are present. Other, non-moving violations may cause underride accidents. For example, a truck driver parked on the shoulder must use road flares or reflective safety items to ensure oncoming traffic can see them.

Trucking companies and trucking manufacturers may also share responsibility for underride crashes. When they do not train their drivers, maintain their fleet, or ensure that their staff is rested for every shift, these entities put other drivers at risk. Additionally, a trucking company might install an underride guard that is inappropriate for the truck; it may be too small, too weak, or incorrectly installed.

Who is usually legally responsible in a truck underride accident?

It is not uncommon for the truck driver, and by extension the truck company, to be fully or partially responsible for an underride accident. This is due to the fact that every underride crash involves a vehicle that is both smaller and closer to the ground than the tractor trailer. The space beneath the truck presents a liability for both truck drivers and trucking companies. If you have been injured in a trucking underride accident, speak to a trucking accident law firm immediately.

What are U.S. Federal Motor Vehicle Safety Standards 223 and 224?

The new U.S. Federal Motor Vehicle Safety Standards 223 and 224 will mean that guards can’t deflect more than 125 mm in crash tests and can’t lift more than 560 mm from the ground; the new U.S. standards will add just under 50 pounds per vehicle. Comparable rules have been on the books in Canada since 2007; approximately 94% of new trailers sold in the U.S. comply with these standards. This safety measure has been shown to offer better protection for sub-compact car occupants (e.g., the Honda Civic or Toyota Camry).

Products by Manac, a truck underride manufacturer, performed well on crash tests. Their products incorporate vertically mounted supports outside the trailer frame rails, attached to a section of reinforced trailer floor. Regulators noted that “trailers that have the main vertical supports for the guard more outboard may not perform as well in full overlap crashes as the trailers that have the vertical supports more inboard.” This finding was concerning, in that 100% and 50% overlap crashes are more frequent than low overlap [<30%] incidents.

Devices built to the Canadian standard perform well enough when hit dead center, and even when a car is offset by 50%. The challenge emerges when only a third of the passenger vehicle’s front end hits the guard. “Even the Canadian regulation does not address that scenario,” says Matthew Brumbelow, senior research engineer.

In the 2010 study, seven out of eight underride models performed adequately when hit from the middle; Six of eight showed potential prevention of several underride crashes at 50% overlap. A 30% offset, however, showed only one of the eight underride models provided sufficient impact resistance.

Will the new trucking underride standards increase trucking costs?

Between the previous standard and the new standard, there actually isn’t much cost difference. The U.S. Government Accountability Office reports that Canadian guards cost about $500 per trailer, whereas those set to earlier U.S. standards cost $229.

The cost is essentially negligible when one considers the potential loss of life that the American standard portend:

An estimated 94% of all applicable trailers already comply with this regulation, the average annual cost of equipping the remaining 6% of trailers that are out of compliance will be $2.1 million.The added average weight — just under 50 pounder per vehicle — will increase fuel costs between $4.43 million – $5.59 million depending on gas prices and inflation.

Will this new truck safety measure keep our roads safe?

These regulations, in theory, will provide greater protection when a car hits a trailer underride guard straight on, or when the front half of a car smashes into the back of a tractor trailer:

According to the NHTSA, the final rule will improve protection in crashes in which a passenger car hits the center of the rear of the trailer, in “50% offset” scenarios (where the width of the passenger motor vehicle overlaps the rear of the trailer.) “NHTSA’s priority is the safety of everyone on our roads,” commented NHTSA Administrator Steven Cliff. “This new rule will improve protection for passengers and drivers of passenger vehicles while also meeting a critical mandate from Congress under the Bipartisan Infrastructure Law.”

While some feel that this is a bold new step in trucking safety, others feel that it is too little, too late. Joan Claybrook, a former NHTSA administrator states, “This final rule…amounts to nothing less than regulatory malpractice,” she said. “Instead of improving protections to reduce underride fatalities and injuries, the agency has gone backward by issuing a rule that 94% of trailers already meet. As such, NHTSA has lowered the bar on public safety instead of ensuring it. This is an affront to the families of underride victims who have been working so hard to have the standard updated.”

Instead of focusing solely on rear guards (which are already implemented by most), the U.S. should be considering a requirement for front/side underride guards. (By comparison, the European Union has required front underride guards for almost 20 years.) A 2012 IIHS study determined that underride guards would reduce injury risk in about three out of every four side-impact truck cases.

A timeline of changes to underride guards

Trucknews.com provides a comprehensive list of underride guard regulations, to which we have added additional information and commentary:

- 1952 – The U.S. Interstate Commerce Commission requires that heavy trucks, trailers, and semi-trailers have a rear-end device to prevent underride accidents. The regulation states that the guard has to be “substantially constructed and firmly attached.”

- 1967 – U.S. actress Jayne Mansfield is among three people killed when their car hits the rear of a tractor-trailer and shears off the car’s roof. As the underride devices are more widely adopted, they become known as Mansfield Bars; however, they are later shown to be less effective at preventing underride accidents than originally thought.

- 1969 — The NHTSA proposes a standard that requires stronger underride guards.

- 1998 – U.S. Federal Motor Vehicle Safety Standard (FMVSS) 223 and 224, governing underride guards, take effect. However, according to the IIHS, “Several types of trucks [were] exempt from the rule, including single-unit trucks, trucks with rear wheels set very close to the back of the trailer and various types of special-purpose trucks.” As the U.S. proposed underride guard upgrades, Transport Canada found a critical gap in the rules: as written, they would fail to protect those inside a 1998 Chevy Cavalier or Honda Civic in a crash at 48 kilometers per hour (approximately 30 mph).

- 1999 – The Canadian Transportation Equipment Association reports on its generic underride guard.

- 2000 — The Centre for Surface Transportation Technology (CSTT) develops a generic underride guard that exceeds FMVSS 223 requirements.

- 2002 – Transport Canada crash tests show that small vehicles were extensively damaged when hitting underride guards built to available standards.

- 2003 – CSTT calls for stronger guards that can absorb more energy.

- 2004 – Transport Canada releases Canadian Motor Vehicle Safety Standard 223 for trailers.

- 2015 — NHTSA issued a proposed upgrade to the rear underride regulations for tractor-trailers in December 2015. The proposed rule would align U.S. regulations with stricter ones in place in Canada since 2007.

- 2011 – IIHS calls for stronger requirements, better protection in offset crashes, and removing rigid fixture tests so guards could only be certified when attached to a trailer. “The current standards allow underride guard designs that fail catastrophically when struck by passenger vehicles at speeds that frequently produce minimal intrusion and injury risk in regulatory and consumer information frontal crash test programs,” the institute said. “The standards should be upgraded to require underride guards that are strong enough to remain in place during a crash, allowing the energy absorbing structures of passenger vehicles to deform and provide protection to their occupants.”

- 2017 – The IIHS introduces voluntary ToughGuard standards, based on crash tests. Throughout the tests, the devices are allowed to deform, break or collapse, but the trailer must not push anywhere beyond the rear surface of a passenger car’s A-pillar.

- 2018 — The National Research Council found that 75% of fatal collisions between heavy trucks and cyclists/pedestrians happen at the front of the vehicle; however, underride guards were not found to have a mitigating effect on accident severity with this population.

- 2020 – The IIHS proposes a quasi-static test for underride guards.

- 2022 — U.S. regulators adopted stricter standards for rear impact guards on tractor trailers.

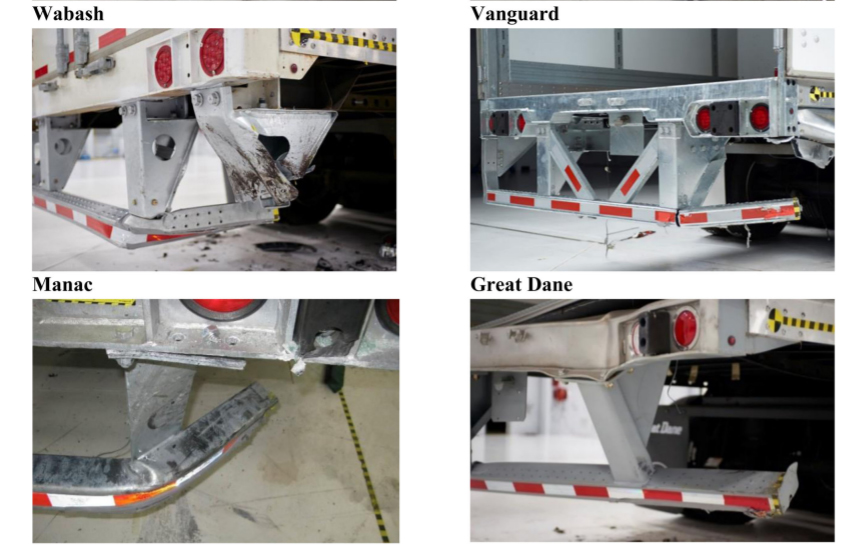

At the time of this writing, nine trailer manufacturers have met voluntary IIHS “ToughGuard” standards; however, they meet the requirements in different ways, as the following photos illustrate:

The future of underride guard safety

In the future, NHTSA seeks to establish a federal advisory committee to study the benefit of side impact guards. Additionally, the organization is calling on individual states’ departments of transportation to track underride crashes, and seeks to help police and first responders identify and record such incidents. The Federal Motor Carrier Administration (FMCSA) is also weighing whether the new underride guard standards should be part of trucks’ annual inspections, as they are for both Canada and Mexico.

While the country and trucking industry slowly adjusts to these new regulations, trucking safety advocates continue to advocate for more stringent rules around underride guards. The IIHS continues to lobby for updates that would protect occupants of smaller vehicles when only a small portion of a car’s width overlaps the underride portion of the truck. The research is clear: stronger underride guard requirements would prevent deaths and injuries in rear- and side-impact truck crashes.

Have you been involved in an underride trucking accident?

Underride crashes can be catastrophic. Many trucking accident survivors live with permanent injuries, including traumatic brain injuries (TBIs), lost limbs and PTSD from the accident. The trauma of an underride accident can cause a cascade of other issues, including an inability to work, disengagement from activities that used to bring joy, and chronic medical issues that may worsen over time.

For these reasons, we highly recommend seeking legal representation with an experienced truck accident lawyer. A competent trucking accident law firm will seek full compensation for your injuries. The process will involve a thorough investigation, not just of the accident but also of your medical needs. Presenting your truck accident case requires a deep understanding of state and federal laws as they apply to the trucking industry. Because these trucking accident cases can be complicated, your attorney should have experience with cases similar to yours.